Special fasteners are produced by manufacturers for moving and fixing heavy loads, it is called an eye bolt and an eye nut. Such fasteners consist of a ring that can be grabbed with a hook or a sling of a lifting mechanism. Such rigging is often referred to as "with a ring", "with an eye", "with an eye".

When using eye-fasteners , it is necessary to take into account the specifics of its application, since special high requirements are imposed on this type of rigging. Eye bolts are produced according to the international standard GOST 4571-73 and according to the German DIN 580. Nuts are made according to DIN 582.

Such types of products are made from carbon steel grade 20, 25, C15E (DIN EN 10084). Stainless steel A2, A3, A4, A5. Carbon steels of such grades can be distinguished by the hardness and strength of the core. Hardware, which is preferred by buyers, is made of carbon steel with zinc coating. Such hardware is produced by forging or stamping.

Not so long ago, eye-fasteners were used exclusively in maritime affairs, today the range of use has become much wider. With the help of such products, it is possible to transport and move machines, mechanisms, metal structures. You can also transport machines, engines, equipment, install supports and masts, tow vehicles. These are just a few examples of the use of eye-fasteners.

When using this product, appropriate fasteners must be attached to the cargo or transported container. For an eye bolt, use a hole with an internal thread, and for an eye nut, use a stud with an external thread.

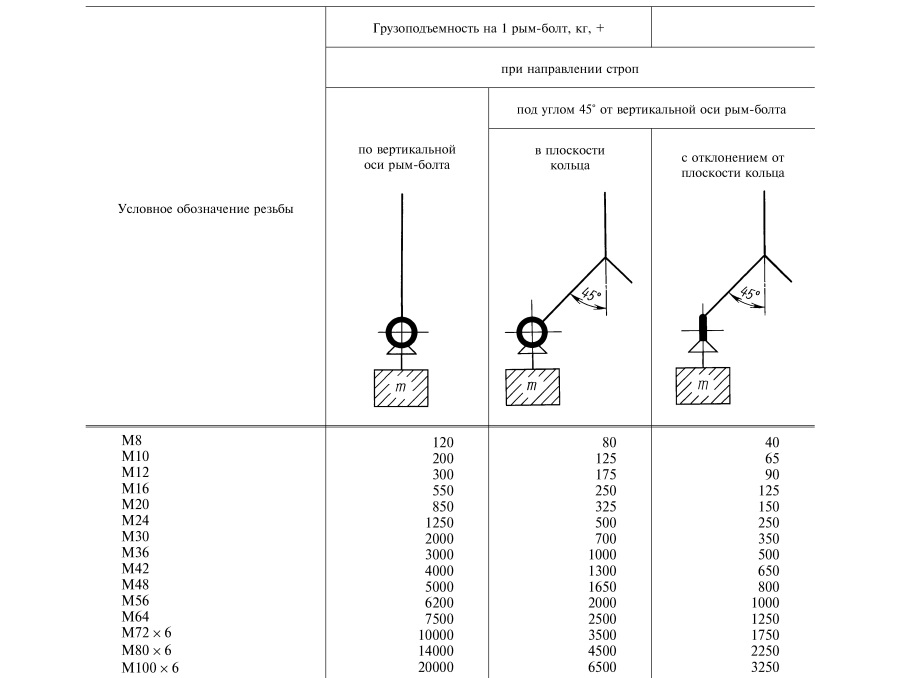

Fasteners are produced in accordance with standards, sizes from M8 to M100.

For each standard size, the lifting capacity of the eye-fastener is set in accordance with the standards and directly depends on the direction of the sling relative to the axis of the thread of the hardware and the plane of the ring. For example, an eyebolt M30 with a load capacity of:

- 2000 kg - the direction of the sling coincides with the axis of the fasteners and slings in the plane of the ring

- 700 kg - direction of the sling with a deviation of up to 45 degrees from the axis of the fastener, the sling is in the plane of the ring

- 300 kg - the direction of the sling with a deviation of up to 45 degrees from the axis of the fastener, the sling deviates from the plane of the ring up to 45 degrees.

Table from GOST 4571-73.

For eye nuts and eye bolts, the following are not allowed:

- dents, holes, chips on the ring

- welding, repairing defects

- notches on the shank

- stripped threads

This type of product can withstand double the load capacity.

Use temperature from -20 С° to +200С°.

You can get advice and buy eye-fasteners by making an application on our website or by calling us by phone +37368327052.