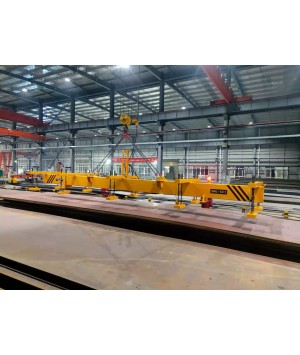

LIFTING BEAM WITH PERMANENT LIFTING ELECTROMAGNET

PERMANENT ELECTROMAGNETIC TECHNOLOGY

Electric current is only used to invert the magnetic field, while the effective force is generated by permanent magnets.

In the event of a power failure, the magnetic force remains constant = 100% safety

SAFETY RATIO 3: 1

For safe lifting, it is necessary to take into account the possible air gap between the contact surface of the magnet and the steel being lifted. This is why all our magnets are designed with a minimum safety factor of 3: 1 with a 0.4mm air gap.

LOAD STATUS DETECTION

An inductive proximity switch and an associated cam attached to the lifting chain prevent accidental demagnetization in the air.

LIFTING CYCLES

The ascent is carried out in 2 stages:

first, the part is lifted with a lower set force, and then immediately in FULLMAG mode (100% of the total force).

2 BUTTONS

To start the demagnetization cycle, you must successively press 2 buttons (SAFE + DEMAG) on the remote control.

REMOTE CONTROL

The magnet is operated from a safe distance. The operator should not be in the immediate vicinity of the load.

SIGNAL LAMP UNIT

The state of the magnet is visually indicated by a transparent LED block. The load can only be moved when the green lamp is on continuously!

INSTRUCTION PANEL

With clear safety instructions for the operator regarding:

- Maximum dimensions of the cargo depending on the thickness of the material

- Maximum overhang depending on the dimensions of the material

Viewed products